Açıklama

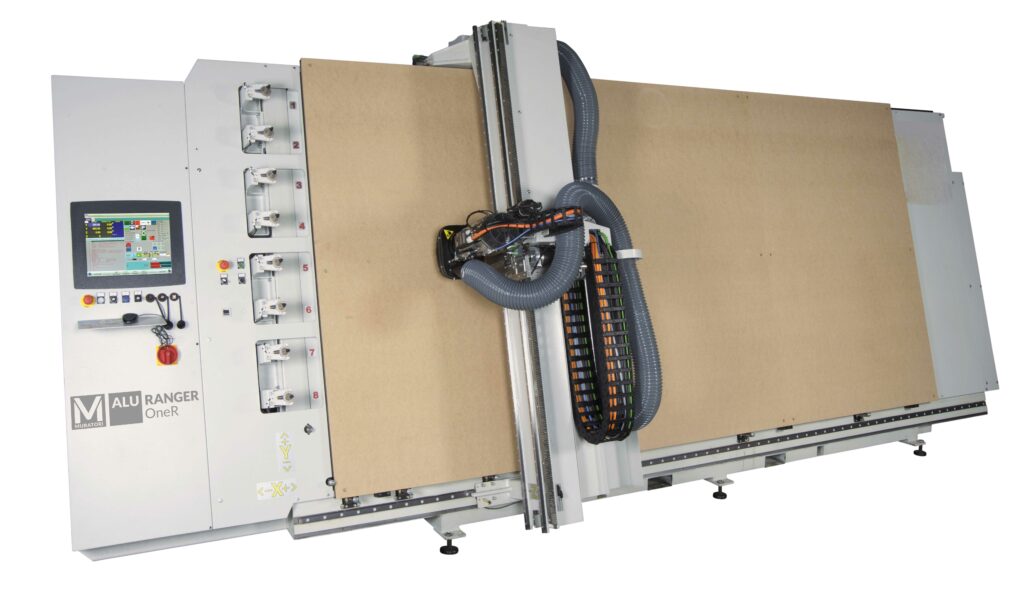

Alu Ranger oneR

CNC Panel Router with Vertical Table

The ALU Ranger oneR has been designed and equipped to process composite panels and it’s available on oneR 4221 and oneR 6321 models

With the correct choice of tools and optional, it is possible to also process solid aluminium

panels (max 4 mm (5/32) in an alloy suitable for processing), fireproof aluminum

composite panels “MINERAL CORE” and plastic (acrylic and polycarbonate) for façades, transport industry, interior design and visual communication.

The machine can process different types of panels by using the adequate tools, rotation speed,

the right feeding speed and lubrication when processing.

The machine can be equipped with loading and unloading systems to further increase daily

productivity.

Alu Ranger oneR 4221 Tech Spec

Vacuum working table for panel holding: oneR 4221 4.200×2.100 mm(14’ x 6’ 11’) divided in 6 zones, with MDF martyr board

– Nr. 1 vacuum pump 250 m³/h

– Nr. 24 vacuum zone combinations for rapid selection according to composite panels

– Nr. 7 origin pop-ups bearing stops, for easy panel sliding: Axis X nr. 1 and Axis Y nr. 6

– oneR 4221 Weight: approx 3.300 Kg – 7.275 lb

Alu Ranger oneR 6321 Tech Spec

Vacuum working table for panel holding: oneR 6321 6.300×2.100 mm (20’ 8’’ x 6’ 11’’) divided in 8 zones with MDF martyr board

– Nr. 2 vacuum pumps 250 m³/h (tot. 500 m³/h)

– Nr. 32 vacuum zone combinations for rapid selection according to composite panels

– Nr. 9 origin pop-ups bearing stops, for easy panel sliding: Axis X nr. 1 and Axis Y nr. 8

– oneR 6321 Weight: approx 4.300 Kg – 9.480 lb

Standard Equipment (oneR 4221 and oneR 6321)

– Automatic reduction of the vacuum managed by the control panel, (PATENTED), which allows the detachment of the machined pieces, granting maximum precision and sealing

– Semi-automatic selection of vertical vacuum zones from control panel

– Rapid manual selection of horizontal vacuum zones according to panel size (1.000–1.250–1.575

– mm) (39’’-50’’-62’’)

– Pneumatic control of end stops with safety sensor connected to PLC

Axis “X” movement with closed bridge technology

– Upper motorization and translation speed up to 30 m/min (1181 IPM)

– Tilted toothed gear rack, hardened and rectified with automatic lubrication

– Rectified and tilted toothed pinion. Connected directly on the motorization axis

– Linear guides with ball bearing pads and automatic lubrication

Axis “Y” movement

– Translation speed up to 30 m/min (1181 IPM)

– Tilted toothed gear rack, hardened and rectified with automatic lubrication

– Rectified and tilted toothed pinion. Connected directly on the motorization axis

– Linear guides with ball bearing pads and automatic lubrication

Axis “Z” movement

– Translation speed up to 10 m/min (394 IPM)

– “Z” movement on linear guides and pads with automatic lubrication

– “Z” motorization on endless ball bearing screw with automatic lubrication

R80A Operating Head Composition, R80A Routing Head T1

– HSD Electro-spindle, 8 kW, ISO 30, speed rotation adjustable by PLC from 3.000 to 24.000 RPM

– Automatic tool storage with Nr. 8 positions for ISO 30 cones on side of working table with cone detecting sensor

– Nr. ISO 30 cones with ER32 collets: Nr. 1 x Ø10 mm, Nr. 2 x Ø6 mm

– Nr. 1 Cutter head to rectify the sacrificial board + Nr. 1 x Ø 120 mm ER 32 collet complete with ISO 30 cone

Tools’ kit for aluminum composites with PE core:

– Nr. 1 x Router bit Ø4 mm

– Nr. 1 x Router bit Ø6 mm

– Nr. 1 x Router bit V 90° Ø10 mm

– Max Max translation speed (rapid): axes “X” and “Y” 30 m/min (1181 IPM), axis “Z” 10 m/min (394 IPM)

– Max. translation speed when processing with flute tools supplied on ACM with PE core: axes “X” and “Y” 10 m/min, (394 IPM) axis Z 4 m/min (157 IPM)

Numerical Control

– Nr. 3 controlled and interpolated axes (X-Y-Z) –

– Nr. 1 Ethernet port for network connection and Nr. 1 x USB port

– 16/9 tiltable TFT LCD colour screen

– Automatic tool length presetting

– Connection to company network by “IP” address

– Automatic start of dust extractor upon activation of T1 spindle

Machine PC

– Possibility in case of PC malfunctioning to operate machine directly with CNC

Minimum features:

– Processor Intel® Core™ i3

– RAM Memory 1x8GB DIMM

– Hard Disk 256 GB SSD

– 2 x Network Board LAN 1 GB

CAD-CAM Software programming, DDX “X-CAM EASY ALU”

– 3D graphics and realistic photo display of the project

– Interactive editing and dimensioning of geometric entities and free drawing

– Import of DXF, CAL, HPGL, ISO files

– Database and set up graphic tools, tool profiles and customizable tool holders

– Cutting program with cutter, drilling, finishing, emptying

– Automatic generation of entry and exit route with interactive graphic editing

– Automatic associative CAM and graphic simulation of the toolpath

– “File Importer” plug-in for automatic processing of 2D projects oriented to the world of architecture and of plastic: from the import of pre-existing projects of various formats to the automatic nesting calculation, optimized processing and ISO code generation in just a few clicks

– Automatic nesting for flute tools “True Shape 1” 0 and 90°: separate production management, panels stock, waste, estimate of time / costs and generation of information for labels with barcodes

Other Features

– Guard on the operating heads with dust collection hood Ø125 mm

– Pneumatic System (CE norm compliant) with filter/pressure regulator with outflow of condensation

– Electrical system and side guards with photocells CE compliant

– Standard Voltage V400/50/3

Not included

– Power supply cables with plugs

– Compressed air supply hose

– Dust suction hose (see optional)

– Tools for working with materials other than aluminum composites

– Recommended dust collector “RL 125” with aspirated air speed min. 30 m./sec and 1.900 m³/h

Değerlendirmeler

Henüz değerlendirme yapılmadı.